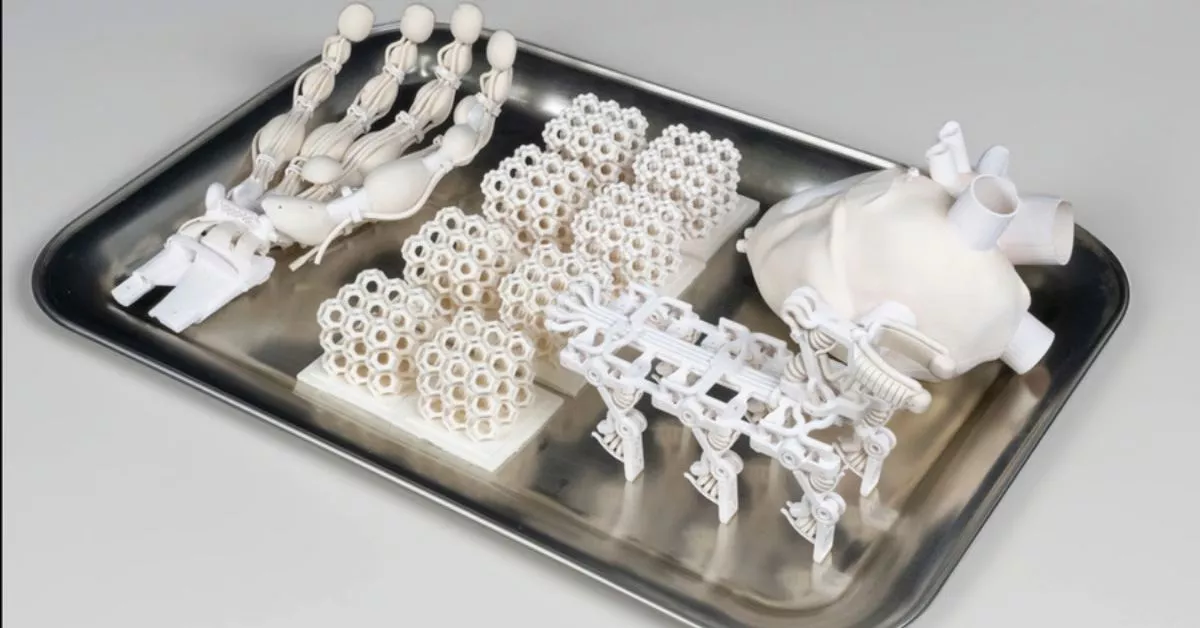

MIT’s advancements in 3D printing technology have reached new heights, pushing the boundaries of medical innovation. Researchers at the Massachusetts Institute of Technology (MIT) have unveiled a groundbreaking development that could reshape the field of medicine – a 3D printer capable of creating artificial bones and tendons.

The Breakthrough:

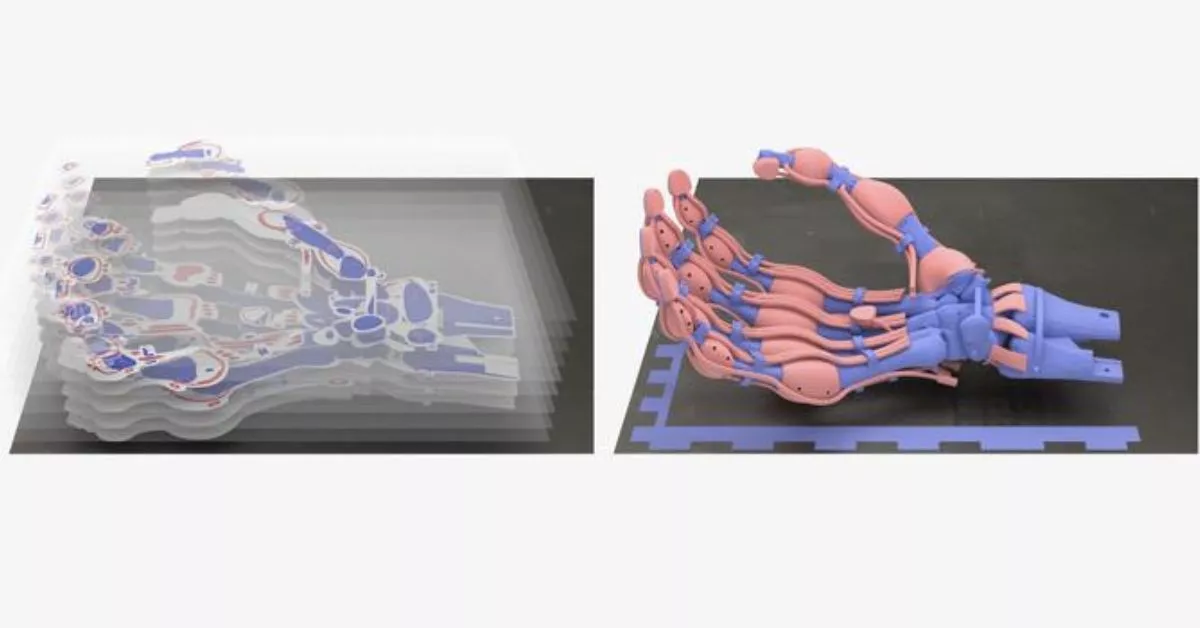

Using cutting-edge materials and precise printing techniques, this pioneering 3D printer has the ability to replicate complex structures found in bones and tendons with astonishing accuracy. It’s not just about mimicking their appearance but also their mechanical properties, making these artificial constructs remarkably similar to the real thing.

The Impact:

The implications of this technological leap are immense. Imagine a world where customized implants, tailored to match an individual’s anatomy, can be created swiftly and efficiently. From repairing fractures to reconstructing damaged tendons, this innovation holds promise in revolutionizing orthopedic surgeries and treatments.

Advantages of 3D-Printed Implants:

- Precision: The ability to precisely replicate the intricate structure of bones and tendons ensures a better fit and functionality of implants.

- Customization: Tailoring implants to a patient’s specific needs reduces the risk of rejection and improves post-operative recovery.

- Faster Healing: With implants closely resembling natural tissues, the healing process can be smoother and quicker.

Future Prospects:

MIT’s breakthrough paves the way for a future where medical treatments are more personalized and effective. As the technology evolves, it may extend beyond bones and tendons, potentially encompassing a wider range of tissue and organ replacements.

Frequently Asked Questions

What is MIT’s 3D printer capable of?

MIT’s 3D printer is capable of creating artificial bones and tendons with a high degree of precision and accuracy. The printer uses a technique called “vision-controlled jetting” to deposit multiple materials simultaneously, creating complex structures that mimic the natural anatomy of bones and tendons.

What are the benefits of using 3D-printed bones and tendons?

There are several potential benefits to using 3D-printed bones and tendons. These benefits include:

- Improved biocompatibility: 3D-printed bones and tendons can be made from materials that are compatible with the human body, reducing the risk of rejection.

- Personalized medicine: 3D-printed bones and tendons can be customized to fit the specific needs of each patient, improving the chances of a successful transplant.

- Reduced healing time: 3D-printed bones and tendons may promote faster healing times, reducing the need for long-term rehabilitation.

What are some of the challenges of using 3D-printed bones and tendons?

There are also some challenges associated with using 3D-printed bones and tendons. These challenges include:

- Cost: 3D-printed bones and tendons are currently expensive to produce.

- Long-term durability: The long-term durability of 3D-printed bones and tendons is still unknown.

- Regulatory approval: 3D-printed bones and tendons are not yet approved by the FDA for clinical use.

What are the future applications of 3D-printed bones and tendons?

3D-printed bones and tendons have the potential to revolutionize the field of medicine. Some of the potential future applications of this technology include:

- Bone grafting: 3D-printed bones could be used to replace damaged or diseased bones.

- Tendon repair: 3D-printed tendons could be used to repair damaged or torn tendons.

- Tissue engineering: 3D-printed bones and tendons could be used to create new tissues for a variety of medical applications.

What is the current state of research on 3D-printed bones and tendons?

Research on 3D-printed bones and tendons is still in its early stages, but there have been several promising developments. For example, researchers have successfully 3D-printed bones that have been implanted in animals with good results.

What are the ethical considerations of using 3D-printed bones and tendons?

There are some ethical considerations that need to be addressed before 3D-printed bones and tendons can be widely used in humans. For example, it is important to ensure that this technology is used in a safe and effective manner, and that it is not used to create human-animal hybrids.

Conclusion:

The convergence of 3D printing and medical science at MIT signifies a monumental step forward in healthcare. The ability to create artificial bones and tendons with such precision opens doors to a new era of regenerative medicine, offering hope for countless patients seeking improved treatments and faster recoveries.

This innovation stands as a testament to human ingenuity and the potential of technology to transform lives. MIT’s 3D printer is not just printing objects; it’s printing a future where medical interventions are more advanced and accessible than ever before.

Overall, MIT’s 3D printer has the potential to revolutionize the field of medicine by creating artificial bones and tendons that are more biocompatible, personalized, and durable than traditional treatments. However, there are still some challenges that need to be addressed before this technology can be widely used in humans.